Condition Base Monitoring Solution for electrical equipments.

READERS

The latest generation of AMS01 readers is the core element of the measurement system.

Available in three versions, they are dedicated to equipment monitoring with TSA-EV11 wireless passive SAW temperature sensors, a wired environmental sensor EXT-ENV-SENS and UHF partial discharge detection.

- AMS01-T: Temperature monitoring only (WIKA #14578091).

- AMS01-P: Partial discharge monitoring only (WIKA #14578102).

- AMS01-TP: Temperature & partial discharge monitoring (WIKA #14578105).

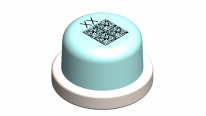

TEMPERATURE SENSORS

TSA-EV11 temperature sensors are passive and wireless.

Available in fifteen models, they accurately measure the surface temperature of electrical conductors.

- TSA-EV11-01: Sensor reference 1 (WIKA #14578144).

- TSA-EV11-02: Sensor reference 2 (WIKA #14578152).

- TSA-EV11-03: Sensor reference 3 (WIKA #14578153).

- TSA-EV11-04: Sensor reference 4 (WIKA #14578156).

- TSA-EV11-05: Sensor reference 5 (WIKA #14578158).

- TSA-EV11-06: Sensor reference 6 (WIKA #14578160).

- TSA-EV11-07: Sensor reference 7 (WIKA #14578163).

- TSA-EV11-08: Sensor reference 8 (WIKA #14578166).

- TSA-EV11-09: Sensor reference 9 (WIKA #14578168).

- TSA-EV11-10: Sensor reference 10 (WIKA #14578172).

- TSA-EV11-11: Sensor reference 11 (WIKA #14578177).

- TSA-EV11-12: Sensor reference 12 (WIKA #14578180).

- TSA-EV11-13: Sensor reference 13 (WIKA #14578184).

- TSA-EV11-14: Sensor reference 14 (WIKA #14578208).

- TSA-EV11-15: Sensor reference 15 (WIKA #14578209).

RF ANTENNAS

AN-F1 RF antennas are passive.

Available in five models with specific cable lengths, they are used to interrogate TSA-EV11 temperature sensors and detect partial discharges.

- AN-F1-295: Antenna with 295 cm cable length (WIKA #14578124).

- AN-F1-455: Antenna with 455 cm cable length (WIKA #14578134).

- AN-F1-620: Antenna with 620 cm cable length (WIKA #14578136).

- AN-F1-800: Antenna with 800 cm cable length (WIKA #14578139).

- AN-F1-1000: Antenna with 1020 cm cable length (WIKA #14614807).

ENVIRONMENTAL SENSOR

The envionmental sensor is dedicated to switchgear monitoring as wired ambient temperature, relative humidity and dew point sensor.

- EXT-ENV-SENS: Sensor with connector (customizable cable length – WIKA #14638422).

ACCESSORIES

- FORK-M9-TSA-EV: Metallic carrier with fork for M9 screw for TSA-EV11 sensors fixation mode (WIKA #14578210).

- FORK-M10-TSA-EV: Metallic carrier with fork for M10 screw for TSA-EV11 sensors fixation mode (WIKA #14578211).

- FORK-M14-TSA-EV: Metallic carrier with fork for M14 screw for TSA-EV11 sensors fixation mode (WIKA #14578212).

- RING-TSA-EV: Plastic ring for TSA-EV11 sensors fixation mode (to be used with TIE-WRAPS reference, WIKA #14578214).

- TIE-WRAPS: Tie wraps for TSA-EV11 sensors fixation mode (to be used with RING-TSA-EV reference, WIKA #14578215).

- TERMIN-RES-RS485: 120 Ohms resistance termination for Modbus-RTU (WIKA #14578219).

Why assets monitoring?

TECHNICAL CONSTRAINTS / TECHNICAL WEAKNESSES

- Networks become more complex – renewables, fluctuating generation

- Bi-directional power/load flow

- More operations and stress on equipment: switching, overloads, harmonics

- The infrastructure is aging, impact of new conditions on equipment is unknown

- Environmental events are worsening (global warming)

EVOLUTION OF INDUSTRY GOOD PRACTICES

- Digitalization, INDUSTRY 4.0 or SMART GRID

- High availability and quality requests for the electricity supply (High risk of huge penalty for utilities and risk of financial losses for industrial customer in case of breakdown)

- Higher requirements for security and safety

There are 5 to 10 arc flash explosions in electrical equipment every day in the USA

Source: NFPA 2015 report

What are the main failures?

INCREASE OF THE TEMPERATURE

- Connection faults

- Harmonic

- Overload

DEGRADATION OF THE INSULATION

- Superficial Partial Discharge (PD)

- Internal PD

- Corona PD

Continuous Rising of temperature on critical points and Partial discharges represents 70% of failures!

What are the benefits of an asset monitoring?

The United States Department of Energy found that 75% of breakdowns are eliminated by energy companies that use asset monitoring solutions enabling access to predictive maintenances / condition base monitoring (CBM).

Asset Monitoring solution for predictive maintenance in the energy Markets provides:

- Savings of 12% on planned repairs

- Maintenance costs reduced by 30%

- Unplanned downtime reduced by 75%

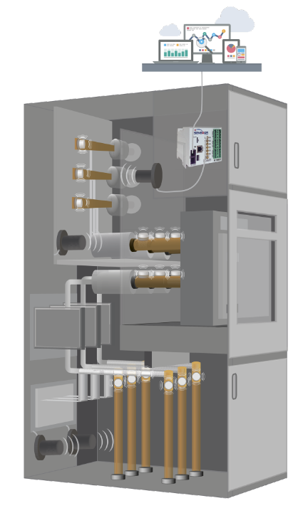

Our solution

MV switchgears instrumented with:

- Wireless battery-less temperature sensors

- High-performance UHF probes

- Environmental temperature & humidity sensor

- Modular IoT platform for data acquisition, analysis & connectivity